MATERIAL HANDLING WHEEL

FOR PALLET JACKS AND FORKLIFTS

Summary

Shark Wheel pallet jack and forklift wheels stand out due to their innovative sine wave technology design. This unique shape significantly reduces rolling resistance, making transportation smoother and more energy-efficient, even with heavy loads. The wheels feature built-in heat vents, which help dissipate heat during extended use, preventing wear and enhancing durability.

The sine wave design excels in obstacle avoidance, allowing the wheels to glide over cracks, debris, and hardware without compromising performance. Ideal for multi-terrain use, these wheels offer superior traction on varied surfaces, ensuring reliable operation in warehouses, loading docks, and outdoor environments. Whether navigating rough terrain or tight spaces, Shark Wheel wheels provide smoother, more efficient movement with less maintenance.

Advantages

Shark Wheel has reinvented the wheel to help pallet jack and forklift users in:

- Rolling Resistance

- Built-In Heat Vents

- Obstacle Avoidance

- Multi-Terrain Use

- Going Over Cracks, Debris, Hardware, Etc.

Trust Shark Wheel Performance

Shark Wheel technology is used by Fortune 500 companies, industry leaders, Bridgestone-Firestone, Samsonite, Harley Davidson, Spyder, the US Military and many others.

Shark Wheel sells industry-leading wheels ranging from skateboarding (14 international competition wins and a Best Seller Badge on Amazon) all the way to agriculture wheels (Top 10 New Products at the World Ag Expo)

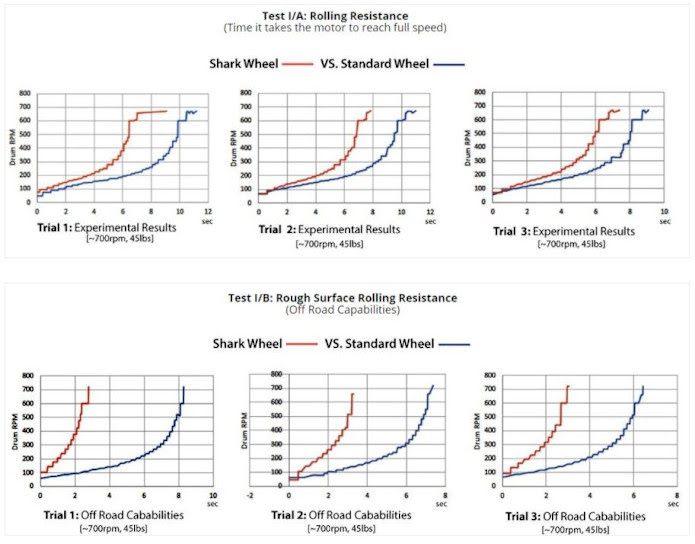

Scientific Testing

- Up to 57% Less Rolling Resistance

- Improved Obstacle Avoidance

- 15% Greater Rebound

Testing Equipment

Tests were performed and the testing rig (seen above) was designed and constructed by a team at the Mechanical Engineering Department at San Diego University.

Conclusion Test I

At a load of 30lbs the Shark Wheel demonstrated an average of 35.52% less rolling resistance at speeds ranging from 0-650rpms (approx. 15.5mph).

When loaded to 45lbs (per wheel) the Shark Wheel demonstrated 60.92% less rolling resistance.

Rolling resistance, also called rolling friction, is an important factor in many industries.

Test II - Conducted by Major Wheel Manufacturer

Another scientific test done by the largest skateboard wheel manufacturer in the world. They compared Shark Wheel to the leading wheels in the market in an apples-to-apples test. Same diameter, same durometer (hardness), same material. 15% greater rebound.

Additional Testing

In separate testing at a Canadian test facility, the Shark Wheel exhibited a longevity/wear advantage.

Tests performed by the German tv show, Galileo (similar to the Discovery Channel), found advantages in rolling resistance and off-road performance.

Most recently, our material handling industry partner (pallet jacks, forklifts), completed 3 years of scientific testing and customer acceptance testing with a Fortune 50 company. Scientific testing showed a wear advantage.

Nature

The wheel mirrors Nature. Everything in Nature alternates. The way fish and sharks swim, the way radio waves move, the way planets move around the Sun and even how humans walk with an alternating gait. Alternating motions Nature's preferred form of motion.

The name Shark Wheel comes from the shape of actual shark jaws. They are a near perfect match: